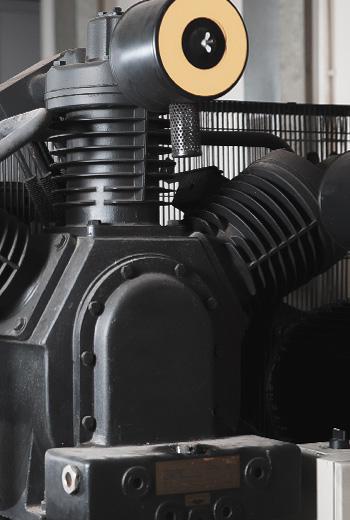

Piston Compressor

A piston compressor is one of the most common forms of air compressors on the market. A piston compressor is commonly the first air compressor you might be using when starting a business or

...

Screw Compressor

Find the suitable rotary screw air compressor for your operations. Mark compressors have a wide range of oil-injected rotary screw compressor options to suit your business needs. From small

...

Compressed air tanks

The compressed air tank is one of the essential components of the compressed air production line. Despite its simplicity, it has a special function and many effects on compressed air quality The

...

Oxygen Generator

The start of the Covid-19 pandemic in 2019 faced the world with a severe challenge. With the spread of this disease across the globe, humans were heavily involved with this deadly virus.

Air dryers

A significant and critical point is selecting a suitable compressed air dryer for each production unit. In addition to the waste of capital, the non-expert selection of air dryers can lead to

...

Compressed air filtration

The increasing need for compressed air and the filtration of this air from pollutants requires having deep experience and acquiring knowledge of technologies related to the functional field of

...

Add comment